|

Shanghai Jiayu Environmental Technology Co., LTD

|

Automatic Large Type Sodium Hypochlorite Wastewater Treatment For Sewage Plant

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Automatic Large Type Sodium Hypochlorite Wastewater Treatment For Sewage Plant Generation principle:</

Automatic Large Type Sodium Hypochlorite Wastewater Treatment For Sewage Plant

Generation principle:

The revolutionary CNJY-L series sodium hypochlorite generator is a newly and for on-site product of NaClO equipment and use for all kinds of needed NaClO disinfected. The sodium chloride solution under the certain voltage effect of the cell, a series of electrochemical reaction within the cell and the resulting solution is the NaClO solution. The main process can be simplified as follows:

NaCl+H2O+DC→NaClO+H2 ↑

The electrode reaction:

anode:2Cl--2e→Cl2

cathode:2H++2e→H2

solution:2NaOH+Cl2→NaCl+NaClO+H2O

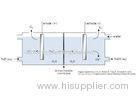

Product system:

Brine preparation part: Including water softener, dissolving tank, salt feeder, mixing

system , etc.

Generation Part : Including Generator, Heated Exchange , Rectifier , Control Cabinet , etc.

Storage Tank Part : Including NaClO tank , blower fan , Level gauge , Hydrogen gas detector , etc

Delivery Part: dosing Pump, flow meter, residual chlorine detector, etc

The advantage analysis of on-site sodium hypochlorite

Compared with traditional disinfection methods:

Water sewage treatment plant 60000 T/D, available chlorite dosing quantity 3 PPM, need 180kg everyday.

Disinfection method | On-site | commercial | UV | |

Making process | It produce a solution of strengths 0.8% and the only PH of 9 and making it less likely to cause scaling | By-product of the chlor-alkali industry, the concentration of 10%, containing excess alkali and harmful impurities | Generally within the ultraviolet fluorescent mercury released from plasma discharge. | |

attenuation | Without attenuation | Attenuation of 5% per day, and also cause excessive Chlorate in dinking water | Usually by the turbidity impact, gradually weakened life six months after the exposure time is short, there is no continuous disinfection capacity, and there may be a problem microorganisms resurrection light, preferably in the case of process water for immediate use, no secondary pipeline better raw water pollution and biological stability of the situation (generally require organic matter content of less than 10μg/L) | |

safety | Safety disinfection method, environmental non-toxic, liquid dosage | Dangerous articles. Risk during transport and storage and easily caused degradable when storage. Short time storage and high transport costs. Liquid dosing | Quartz tube require regular cleaning, heavy workload, each lamp should change the water. Easy to do radiation uniformly over the entire processing space, shaded area exposure | |

Disinfection by-products | Due to weak in chlorine oxidation ability, three material are less, and combined additive, ammonia, potassium permanganate, less by-products | The raw material is Industrial salt, which contain harmful impurities in drinking water and it is bad for health. | None | |

Economic analysis | The investment is a little higher in the early time, but the operation cost is low, and after three or four years it can pay your investment money back | Equipment cost is low, but the high cost of running, and the running costs can not be controlled | Early investment in small, high maintenance costs, large daily operating costs. | |

Dosing Accuracy | Dosing liquid low concentration, can accurately control the amount of chlorine | High concentration, difficult to precisely control the amount of chlorine, dosing hole easily plug fouling | Regular cleaning, the effect can not be controlled and also need regular to test water quality. |

- ECONOMIC ANALYSIS

- On-site Sodium Hypochlorite

Unit raw material consumption:

DC Power consumption : 4.5kW·h/Kg Cl2

Salt consumption :3.5 Kg / Kg Cl2

Daily energy consumption:

Daily power consumption :180 x 4.5 = 810kW·h

Daily salt consumption :180 x 3.5 = 630 Kg

The raw material price :

The average power price :0.6 RMB / kW.h

Edible salt price :0.8 RMB /kg

Daily operation cost :

electricity :810 × 0.6 = 486 RMB

Salt :630 × 0.8 =504 RMB

Daily operation cost:486 +504 =990 RMB / D

UV operation cost Tube :1500 RMB / piece,Need: 8*14*2 = 224 pieces,The service life is about one year.Daily cost::1500*224/365=920 RMB / D

electricity:35.84 kw / set,One day:2*35.84*24*0.7=1204

Daily operation cost:920+1204 =2124 RMB / D

- 10%commercial sodium hypochlorite cost:

10% commercial sodium hypochlorite to the factory price is 130 RMB / T, and covert into active chlorine is 1300 RMB / T, and the daily plant need available chlorine is 180 kg

The daily cost is :13*180=2340RMB / d

- The cost compared On-site sodium hypochlorite with UV and commercial sodium hypochlorite

Available chlorine production | 180 kg/d |

UV running cost | 2124 RMB / D |

Commercial sodium hypochlorite | 2340 RMB / D |

Sodium hypochlorite generator running costs | 990 RMB / D |

The on-site sodium hypochlorite | 1134 RMB / D and 1350 RMB / D |

The on-site sodium hypochlorite system annual saving | 1134*365=41.3 thousands RMB /y |

The costs and benefits of sewage water disinfection by sodium hypochlorite depend on-site specific factors such as power costs, availability of brine water, safety ,and ease of use. Disinfection using hypochlorite is often the least expensive and most appropriate option.

Details :

Work shop :