|

Shanghai Jiayu Environmental Technology Co., LTD

|

Gold Index: 6128

High Integrated PPH Food Storage Tank For Sodium Hypochlorite Dosing Part

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

High Integrated PPH Food Storage Tank For Sodium Hypochlorite Dosing Part PPH food storage tank screw ext

High Integrated PPH Food Storage Tank For Sodium Hypochlorite Dosing Part

PPH food storage tank screw extrusion molding process using winding technology and its quality reached the international advanced level, the main process includes tanks out of winding , external welding , seam welding and pipe installation , etc.

Extruded body wrapped :

Welding tank is wound with PPH screw extrusion unit processed into pellets to make PPH tank molding process. The system uses the extrusion and then wound into a steel mold particles melt tank after PPH process

External welding production :

External welding adopt imported automatic extrusion welding unit enabling the tank achieve a large part of the stress maximum weld a welding molding process . The body of the same nature with the new PPH pellets melt in large weld, and the tank bottom , the tank into one .

Internal welding production :

Welding is the long arm of internal automatic extrusion welding process is that all the most important step in the process . The body of the same nature with the new PPH pellets melt within the weld , and the tank bottom , the tank into one , the same principle and external welding, but with different devices .

Pipe installation :

Pipe installation is the last procedure , the same as narrow version of the bottom welding , which use imported small automatic welding units and making joint pipe and flange welding forming , and then use the openings for the tanks on the size of the corresponding diameter, finally adopt the German MUNSCH portable extrusion welding.

Advantages :

The production efficiency is higher than manual 5-8 times

Good product integrity , no seams , corrosion resistance and leakage resistance

Smooth and beautiful products, achieve body under thick thin, lower prices

Unrestricted of product size and shape

Products for pellet processing, good anti-aging properties

Highest mechanization , automation , product quality and stability

Products can be designed to withstand the stress characteristics of the weld specifications, so as to give full play to the integrity of welds

Product integrity, and weld the parent body, corrosion resistance, leakage resistance

Can reduce the flash, seams smooth and beautiful

In PPH particle compound added UV absorbers, anti-aging, long service life.

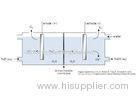

Nominal | Main dimensions |

| |||||||

L | H | A | B | C | D | e1-2 | |||

1 | 1000 | 1100 | 1350 | - | 50 | 50 | 25 | 25 | |

3 | 1600 | 1200 | 1650 | 400 | 50 | 50 | 25 | 25 | |

5 | 1600 | 2250 | 2650 | 400 | 50 | 50 | 25 | 25 | |

8 | 2000 | 2200 | 2700 | 400 | 80 | 80 | 25 | 25 | |

10 | 2000 | 2800 | 3400 | 500 | 80 | 80 | 25 | 25 | |

15 | 2200 | 3550 | 4100 | 500 | 80 | 80 | 50 | 25 | |

20 | 2500 | 3600 | 4200 | 500 | 80 | 80 | 50 | 25 | |

30 | 2800 | 4400 | 5100 | 500 | 100 | 100 | 50 | 25 | |

40 | 3000 | 5100 | 5850 | 500 | 100 | 100 | 50 | 25 | |

50 | 3200 | 5600 | 6400 | 500 | 100 | 100 | 50 | 25 | |

60 | 3600 | 5250 | 6200 | 500 | 100 | 100 | 50 | 25 | |

80 | 4000 | 5650 | 6650 | 600 | 100 | 125 | 80 | 25 | |

100 | 4000 | 7300 | 8300 | 600 | 100 | 150 | 80 | 25 | |

120 | 4000 | 9000 | 10000 | 600 | 100 | 150 | 80 | 25 | |

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Shanghai Jiayu Environmental Technology Co., LTD [China (Mainland)]

Business Type:Manufacturer

City: Shanghai

Province/State: Shanghai

Country/Region: China (Mainland)